Re-Plumbing

Hey, so. That was a long break from writing on the blog. Not intentionally, and it's not like we've been doing nothing, but well. Sorry about that.

So let me catch you up on some stuff.

We had an inspection of the electrical, which we passed, yay. At the same time Noel asked the inspector to look at the start of our plumbing, and he noted this:

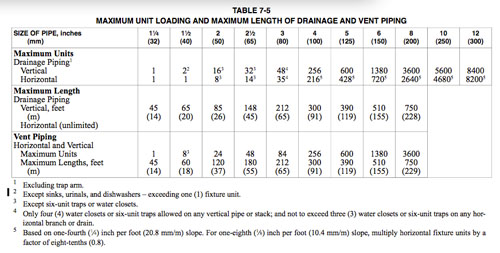

That's the vent from our downstairs toilet, and in the California Plumbing Code the minimum size of a vent from a water closet is 2", not 1-1/2". Do they say this explicitly? Of course not. They say it in a tiny little footnote that I missed, and then only by implication.

(That's footnote 3, and tell me how clear that is.) (This is the 2010 CPC, because that's what code our permit is under; if the code changes while you have a permit open and unexpired, you do not need to start using the new code.)

To be fair, architects aren't called on to know details of vent sizing pretty much at all.

So we had to redo the one vent we thought was pretty much finished. I made a list of fittings needed, dropped by Pagano's, and we set today as the day to get it done.

The first set was to go through and line up the various fittings with the way we thought they would go together. We had some problems with how things went together because we glued some pieces together before really trying them in place. So we decided to be more methodical about the process this time.

We lined up the fittings I'd bought and talked through the process, comparing them to the ones we had installed.

Then we cut out the parts that were not right. We didn't have to remove all the drain and vent pipes we'd installed, but we did have to cut them apart pretty dramatically. And because of the fact that ABS is chemically welded together, none of the pieces we cut out were reusable.

The process of redoing the work was actually a bit faster than when we did it initially. We learned from our mistakes the first time around, I guess.

We started from the top this time, and when we got into the crawlspace Noel went down there and I stayed above. We find that arranging ourselves that way means less dragging yourself around through tight spots and the maze of heat ducts in the basement.

Also, Noel was pretty psyched to try out his new headlamp, which was a great success.

Then it was all finished.

And because we'd been more efficient in the installation this time, we had a bunch of leftover fittings (I will be taking them back, because they add up to quite a bit).

We did stop before gluing the last bit together to check this:

![]()

I knew there were some cases where a vent line has to be connected above the centerline of the pipe. It turns out that that is when the pipe is less than 45 degrees (the standard for what is considered "horizontal" in the code). But we were good for any angle we needed since we already knew that by code, the vents have to be vertical until they are at least 6" above the weir (or overflow height) of the fixture they serve. Phew.

We still have to figure out the upstairs bathroom plumbing, which we are going to start on tomorrow.

And I have a few more posts to write that I didn't get around to over the last month. So bonus post week, I guess.

posted by ayse on 08/16/14